We “IVM Engineering”,

"Committed to industrial Values.. by Manufacturing Quality Products"Knife Edge Gate Valve

Product Details

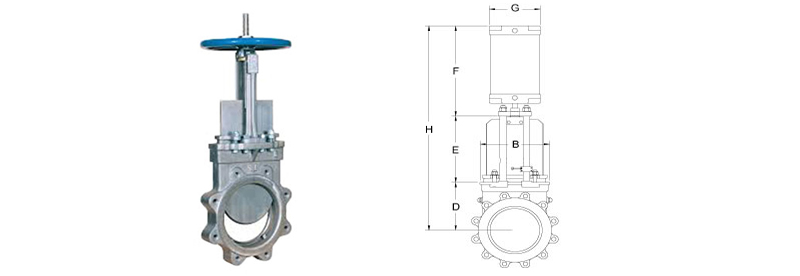

“IVM” Knife Gate Valves are generally unidirectional valves and act as an excellent hopper isolation valves with their ability to cut through flowing media and closed by dislodging any material in the seating area.

Knife-Edge Gate Valves withstand high temperature & abrasive slurries in Mining, Steel, Power, Chemical, Sugar, Pulp & Paper Industries Ideal for high-density Slurry Lines.

• Mfg. Std. :- MSS - SP 81

• Testing Std MSS - SP 81

• Operation : Wheel Optd. / Gear Optd. / Chain Wheel Operated / Pneumatic Cylinder Operated / Electrical Actuator operated

• End Connection Wafer / Wafer Lugged type / Double Flange type to ANSI B 16.5, DIN PN10, Others on Request

• Working Pressure : 10 Kg/cm2 for Size upto 16” ; 4 Kg/cm2 for size 18” to 32” ; 3 Kg/cm2 for size 34” to 42"

| Material Specification | |

| Body | C.I, WCB CF8, CF8M |

| Gate | ANSI 304 AISI 316 |

| Seat | Metal to Metal(EPDM/VITON/PTFE/NITRILA) |

| Packing | PTFE Impreg. Synth. Fibre |

| Gland Follower | Ductile Iron CF, 8, CF8M, WCB |

| Stem | AISI 304 |

| Stem Nut | Gun Metal |

| Yoke | Carbon Steel |

| Seat Rating | AISI 304 AISI 316 |

| Operated | Chain Wheel |

| Fastners | Zinc Plated Carbon Steel |