Butterfly Valves

We “IVM Engineering”,

"Committed to industrial Values.. by Manufacturing Quality Products"Butterfly Valve

Product Details

Center Rubber Lined, Concentric, Slim-Seal Design,

Wafer Type, Flangeless, Wafer / Lug / Double Flanged

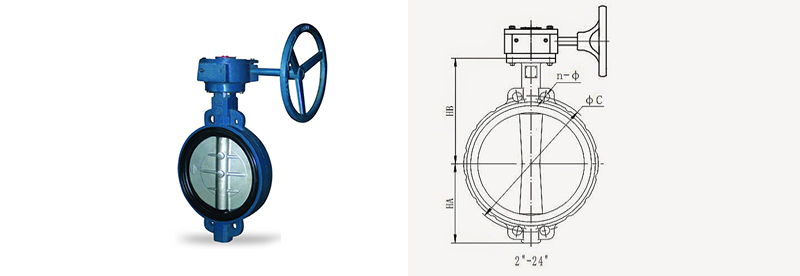

“IVM” Offers Wafer Type Butterfly Valve have been developed with extensive application, design and manufacturing expertise. “IVM” High Performance Slim-Seal, Concentric design Butterfly Valves are reliable, maintenance free shutoff with permanently gas-tight seal with an integrally moulded or replaceable elastomer body liner. Butterfly Body having two nos. flange locating holes for sizes up to 12 and from size 14 and above 04 nos. for easy alignment of valve during installation. Flange locating hole confirm to as per ANSI B 16.5 Class 125 & Class 150 / BS 10 Table D, E, F / PN 6, PN 10, PN 16 or other international standard. High performance butterfly valves are also available with Full-Lugs type body with raised faces and flanged ends connection.

“IVM” Offers Butterfly Valve Wafer Type, Slim-Seal design, maintenance free shutoff. This butterfly valves excess other conventional valves such as gate valve and globe valves in all aspects, especially in terms of light weight, less number of component, no flange gaskets required and economical operation and maintenance costs.

“IVM” Offers Slim Seal design Butterfly Valves body seat mechanism have a very low torque, tight shut off with zero leakage, compact actuator selection, and long life smooth easy operation. The slim-seal, center disc design valves are widely available with different combination of body, seat & disc materials to satisfy the need of most industrial application.

Salient Features :

• Concentric, Slim-Seal Design

• Greater Sealing Capacity

• Soft Seat Design

• Lower Torque with any fluid

• Permanently tight closure

• Bi-Directional Valve

• Optimum operation under Vacuum Condition

• Suitable for On-off as well as Throttling Service

• Materials for almost all media

• Short Face To Face Dimension

• Wafer Design Body

• Long Service Life

• Smooth, Easy Operation

• Maintenance Free Version

• Less Weight, Easy To Install

Special Options :

• Off Set Disc Design Butterfly Valve for high pressure & temperature service.

• Moulded / Replaceable Seat option

• Gear / Pneumatic Rotary Actuator Operated

• P.T.F.E. (PFA/FEP) Lined Butterfly Valve

• Flanged End, Butterfly Valve

• Damper Type Butterfly Valve for High Temperature Air Service

• Off Set Disc Design Butterfly Valve for high pressure & temperature service

• Tailor Made Valve

Standard Test :

Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test.

Seat Test: 1.5 times the working pressure with water.

Function / Operation Test: At the time of final inspection, each valve and its actuator (Flow-Control Lever / Gear / Pneumatic Actuator), under goes a complete operating test (Open/Close). This test carried out without pressure and at ambient temperature. It ensures the correct operation of the valve / actuator assembly with accessories such as solenoid valve, limit switches, air filter regulator etc.

Special Test: On request, any other test can be carried out according to special instruction by client.

“IVM” Offers Wafer Type Butterfly Valve have been developed with extensive application, design and manufacturing expertise. “IVM” High Performance Slim-Seal, Concentric design Butterfly Valves are reliable, maintenance free shutoff with permanently gas-tight seal with an integrally moulded or replaceable elastomer body liner. Butterfly Body having two nos. flange locating holes for sizes up to 12 and from size 14 and above 04 nos. for easy alignment of valve during installation. Flange locating hole confirm to as per ANSI B 16.5 Class 125 & Class 150 / BS 10 Table D, E, F / PN 6, PN 10, PN 16 or other international standard. High performance butterfly valves are also available with Full-Lugs type body with raised faces and flanged ends connection.

“IVM” Offers Butterfly Valve Wafer Type, Slim-Seal design, maintenance free shutoff. This butterfly valves excess other conventional valves such as gate valve and globe valves in all aspects, especially in terms of light weight, less number of component, no flange gaskets required and economical operation and maintenance costs.

“IVM” Offers Slim Seal design Butterfly Valves body seat mechanism have a very low torque, tight shut off with zero leakage, compact actuator selection, and long life smooth easy operation. The slim-seal, center disc design valves are widely available with different combination of body, seat & disc materials to satisfy the need of most industrial application.

Salient Features :

• Concentric, Slim-Seal Design

• Greater Sealing Capacity

• Soft Seat Design

• Lower Torque with any fluid

• Permanently tight closure

• Bi-Directional Valve

• Optimum operation under Vacuum Condition

• Suitable for On-off as well as Throttling Service

• Materials for almost all media

• Short Face To Face Dimension

• Wafer Design Body

• Long Service Life

• Smooth, Easy Operation

• Maintenance Free Version

• Less Weight, Easy To Install

Special Options :

• Off Set Disc Design Butterfly Valve for high pressure & temperature service.

• Moulded / Replaceable Seat option

• Gear / Pneumatic Rotary Actuator Operated

• P.T.F.E. (PFA/FEP) Lined Butterfly Valve

• Flanged End, Butterfly Valve

• Damper Type Butterfly Valve for High Temperature Air Service

• Off Set Disc Design Butterfly Valve for high pressure & temperature service

• Tailor Made Valve

Material | |

| General Design & Manufacturing |

API 609 category A / BS 5155 / MSS SP-67 |

| Valve

Face to Face Dimensions |

Short wafer or Wafer

lugged as per ISO 5752 Tab 5 & API 609 category A |

| Top Flange Drilling | ISO 5211 part II |

| Valve

Inspection and Testing |

API 598 |

| Flange

Standard Conformity |

ANSI 150, DIN PN6 / PN10,

PN16, JIS 5K / 16K BS 10 Tab D & E, IS 6392, PN 1.6 / 1.0 |

| Valve Type | Centric Disc Butterfly Valve with a Single Piece Rubber lined body, , Offset Disc Type, Double Offset & Triple Offset Type |

| Body Type | Short Wafer (Sandwiched between Flanges) / Double Flange Type |

| Seat Type | Integrally Moulded with the Body / Replaceble |

| End Connection | Wafer Sandwiched / Double Flange Type |

| Pressure Rating | PN 10 / PN 16, PN 25, PN 40, 150#, 300# |

| Operating Temperature Range |

-25°c to 200°c (Depending on MOC) |

| Seat Leakage | Tight Shut off |

| Operation | Hand lever, Worm Gear Boxes, Pneumatic Actuator, Electrical Actuator |

| Size Range | 40 NB to 1200 NB |

Material of Construction | |

| Body | C I (IS 210 Gr. FG 260) / SGI (GGG40) / WCB (ASTM A 216 Gr. WCB) / CF8 (ASTM A 351 Gr. CF8) / CF8M (ASTM A 351 Gr. CF8M) |

| Disc | SGI / WCB / CF8 / CF8M |

| Seat | Nitrile / Neoprene / EPDM / Silicon / Viton / PTFE / Hypalon |

| Shaft | AISI 410 / 304 / 316 |

Standard Test :

Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test.

Seat Test: 1.5 times the working pressure with water.

Function / Operation Test: At the time of final inspection, each valve and its actuator (Flow-Control Lever / Gear / Pneumatic Actuator), under goes a complete operating test (Open/Close). This test carried out without pressure and at ambient temperature. It ensures the correct operation of the valve / actuator assembly with accessories such as solenoid valve, limit switches, air filter regulator etc.

Special Test: On request, any other test can be carried out according to special instruction by client.